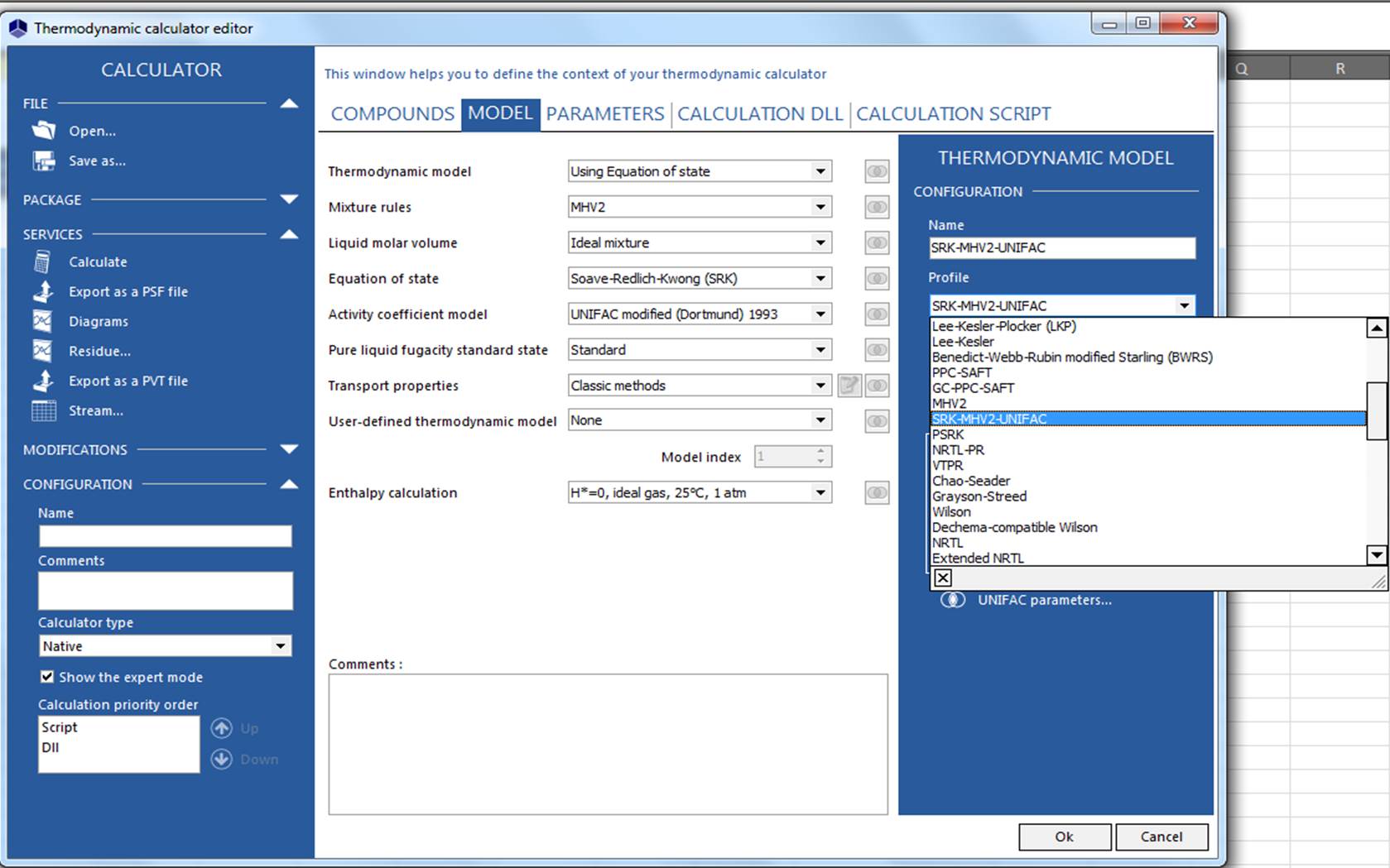

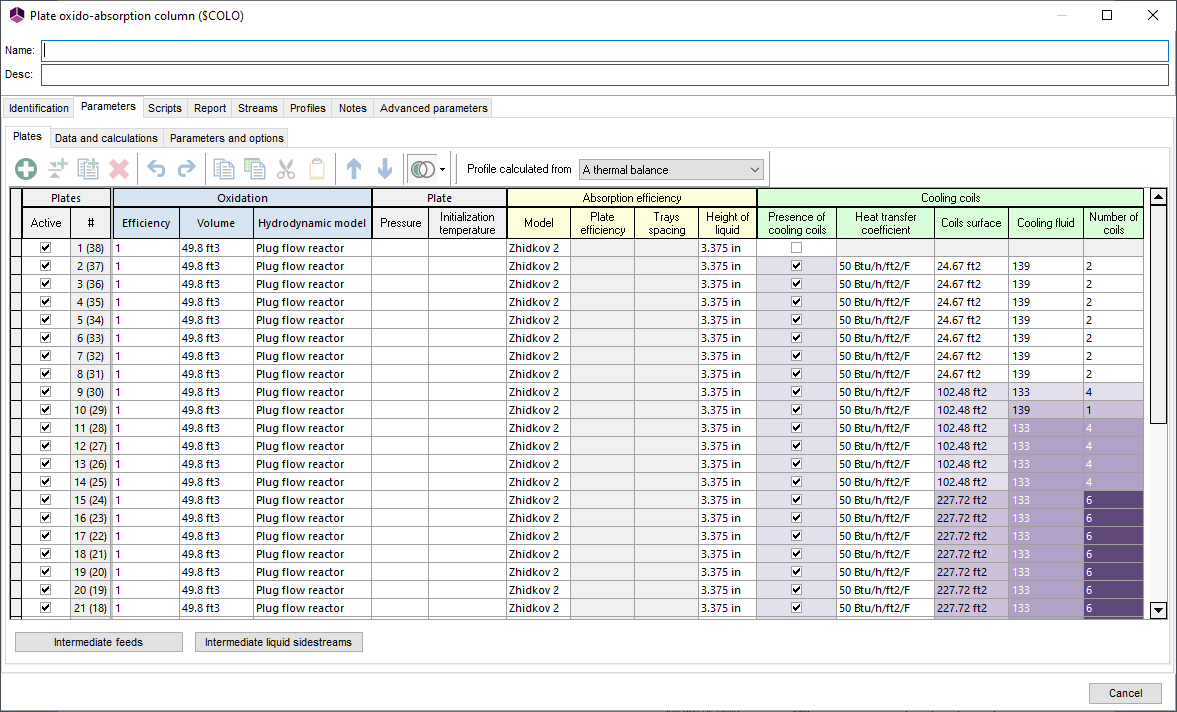

In addition to the unit operation library usually available in general simulation packages, ProSimPlus HNO3 offers a full set of equipment specific to nitric acid production processes, in particular: The unit operations required to represent your processes accurately It is generally not the case in other processes and therefore not taken into account in standard simulation software. It is necessary to take into account sizing parameters (pipes volume, absorption column trays spacing,…) at early process design stage as, when adding oxidation volumes, they affect the mass and energy balances. The complexity of the physical and chemical phenomena involved in nitric acid processes (chemical reactions in gas phase in nearly all the equipment pieces, thermodynamic properties not easy to model,…) and the specificity of the equipment used in these units make the simulation of these processes nearly impossible with a general purpose simulation software.

Thanks to a reliable modeling of the unit steady-state behavior, it helps to generate significant improvements in efficiency and profitability as well as to increase reactivity when facing new regulations. It is used in design phases as well as in plant operations for process optimization, unit debottlenecking or plant revamping. It allows engineers to represent accurately and to analyse processes in which the absorption of nitrous vapours and associated complex physico chemical phenomenon intervene (nitrogen monoxide oxidation reactions, nitrogen dioxide dimerization reaction, nitrogen oxides absorption in nitric acid aqueous solutions.).

ProSimPlus HNO3 is a unique process engineering tool, specifically designed to model nitric acid production plants and nitrous vapors absorption units. ProSimPlus HNO3 Simulation and optimization of nitric acid plants and nitrous vapors absorption

0 kommentar(er)

0 kommentar(er)